PAD MOUNT TRANSFORMER

R Line Pad Mount Transformer is a distribution transformer manufactured at AK Power Solutions authorized overseas suppliers in compliance with U.S. Department of Energy (DOE) conservation standards.

Padmount

The R Line family (available in both Padmount and Substation configurations) offers compact, space optimized power solutions that deliver dependable performance and exceptional installation flexibility. Designed with redundancy in mind, each unit ensures continuous operation even during maintenance or unexpected load shifts, giving data centers the reliability and resilience they can't afford to compromise on.

Substation

Flexibility & Control

Procurement Simplicity

Speed of Energization

Competitive Total Cost of Ownership

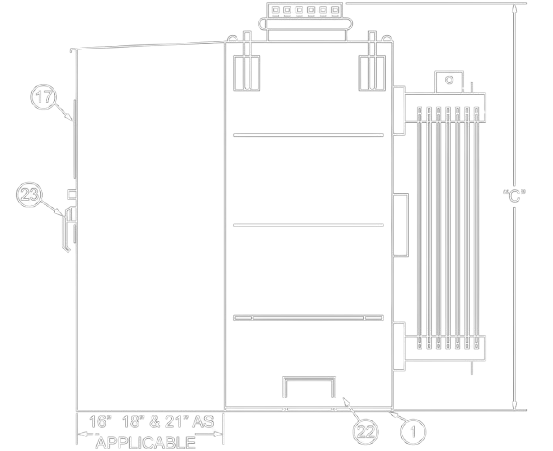

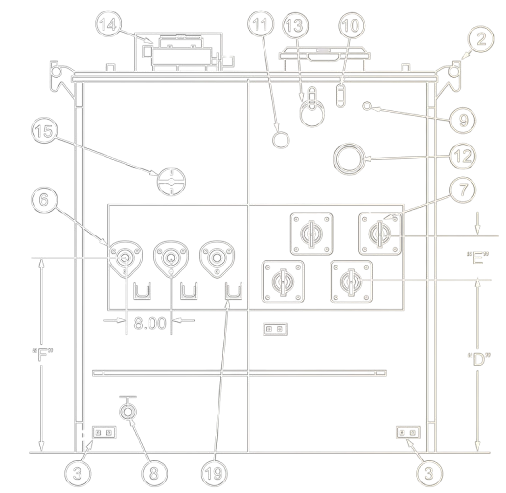

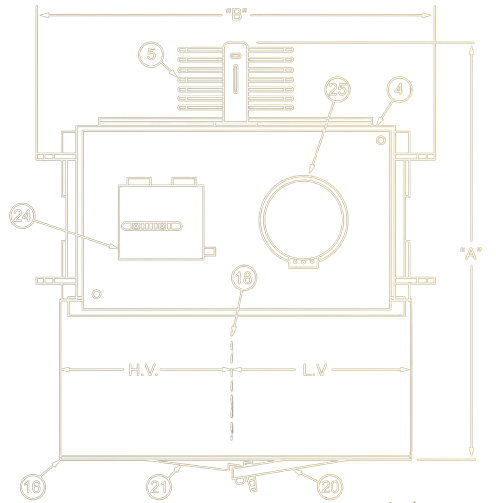

SNEAK PEAK INSIDE our padmount transformer

- 1. Base of Transformer

- 2. Lifting Lugs

- 3. Ground Pads

- 4. Welded Top Cover

- 5. Cooling Radiators

- 6. HV Epoxy Bushing Well

- 7. LV Epoxy Bushing 4, 6 ,8 or 10 hole

- 8. Lower Drain Valve

- 9. Upper Filter Plug

- 10. Pressurization Test Point

- 11. Liquid Level Guage

- 12. Liquid Temperate Guage

- 13. Pressure Vacuum Guage

- 14. Pressure Relief Device (optional)

- 15. Tap Changer

- 16. HV/LV Cabinet, Weld On

- 17. Stainless Steel Nameplate

- 18. Isolating Barrier

- 19. Parking Stands

- 20. LV Compartment Door

- 21. HV Compartment Door

- 22. Jacking Pad

- 23. Padlockable Handle

- 24. Box for Pressure Relief Device

- 25. Manhole with Cover

Weights and dimensions

Typical weights and dimensions of mineral oil filled 3 Phase, aluminum winding, dead front, radial feed, R-Line Padmount Transformer up to 5,000 kVA is shown per IEEE C57.12.34.

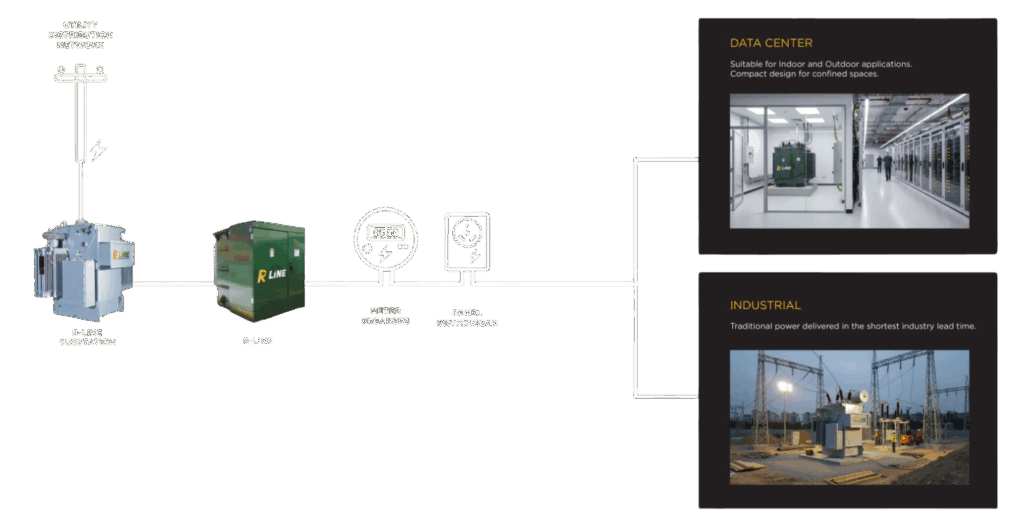

how it works

Data center

Suitable for Indoor and Outdoor applications. Compact design for confined spaces.

Industrial

Traditional power delivered in the shortest industry lead time.

SUBSTATION TECHNICAL SPECIFICATION

Standard Features

- High grade silicon-steel core

- Windings Aluminum or Copper

- No-Load Tap Changer

- Type II non PCB mineral oil (ONAN)

- Reinforced carbon steel tank

- Removable radiators

- Lifting lugs

- Externally clamped high and low voltage bushings

- Pressure relief valve

- Pressure vacuum gauge

- Liquid temperature gauge

- Liquid level gauge

- Drain and sample valve

- Grounding pads

- Ground pads

Optional Features

- Environmentally safe FR3 oil (KNAN, flammable point > 300°C)

- On Load Tap Changer

- Stainless steel tank

- Gauges with contacts

- Auxiliary NEMA 3R/4 control cabinet and terminal box

- Protection and Control device

- Winding temperature gauge

- Fan package (ONAF, OFAF, or KNAF, KFAF)

- Lid mounted pressure relief device

- Rapid pressure relay, with/without seal-in relay

- Lightning arresters

- Electrostatic shielding

- K-rated design to reduce harmonics

- Buchholz relay

- Primary load interrupter switch

- Neutral Ground Resistor

Testing

- All standard commercial testing provided in accordance with ANSI and IEEE.

- Test scripts may be customized to meet customer requirements.

- Factory Witness Testing available at factory or via Zoom videoconferencing.

how it works