From Stick Build to Skid Build – The New Era of EV Infrastructure

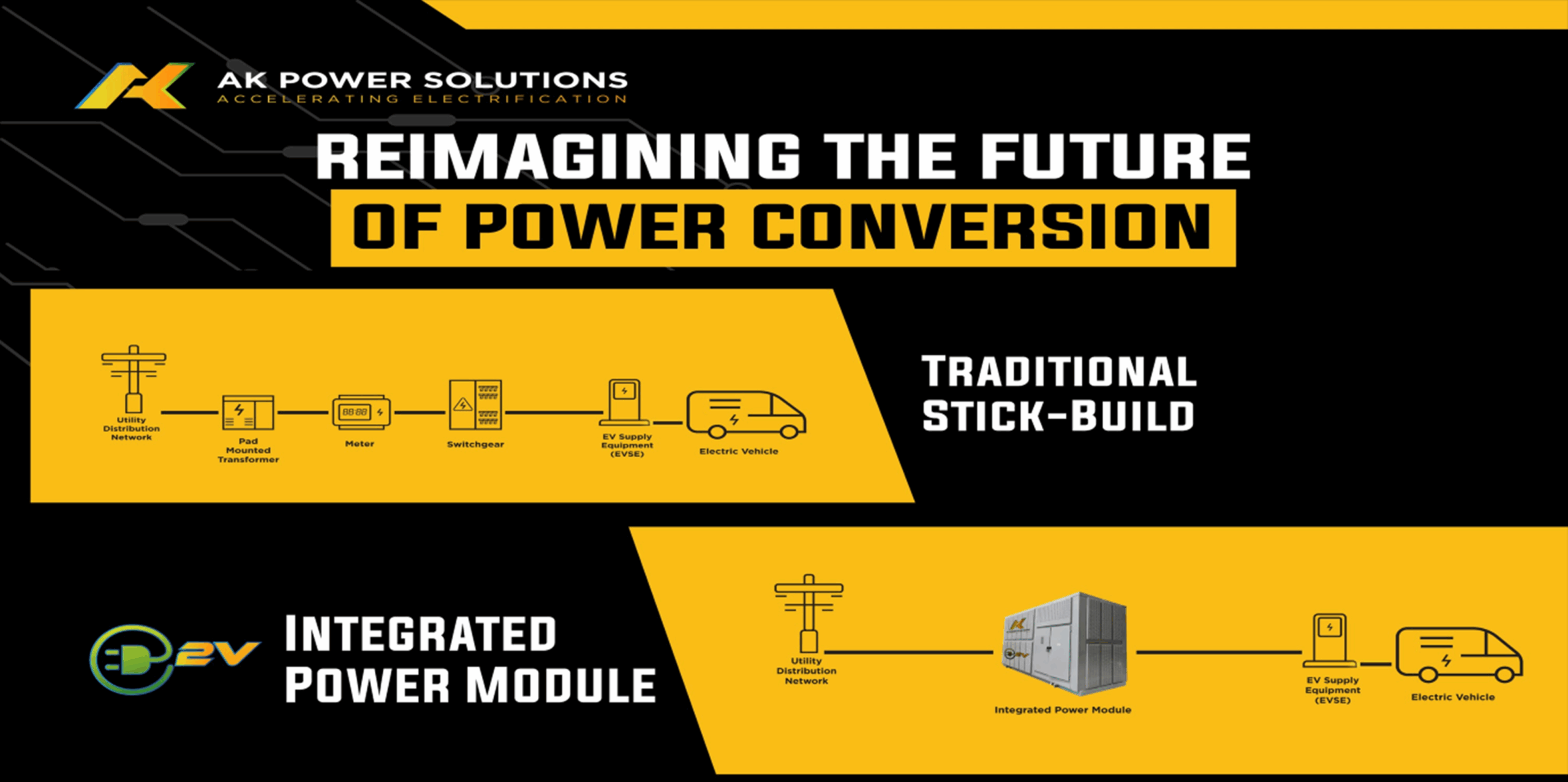

Before EVs began reshaping transportation, EV charging sites were built the old-fashioned way – piece by piece, on-site, using traditional “stick build” methods. Each component-transformers, switchgear, meters, chargers, and controls – was sourced separately and assembled in the field. Familiar? Yes. Fast or scalable? Not even close.

As EV adoption surged cracks in the stick-build approach became impossible to ignore. Long timelines, spiraling costs, and tangled vendor coordination stood in the way of progress. The industry needed something better. Enter: Skid Build solutions.

Why Skid Builds Changed Everything

Skid-based systems consolidate everything into a single, pre-assembled module – streamlining installation, reducing on-site complexity, and enabling repeatable scalable deployments.

Tesla helped kick off this shift in 2023 with prefabricated Supercharger stations. DC-America took it further, integrating switchgear, metering, and chargers into one plug and play skid solution. But the next leap forward? That belongs to AK Power Solutions.

Our E2V Integrated Power Module (IPM) brings a new level of efficiency to EV infrastructure. Built with flexibility, speed, and utility-readiness in mind, it’s more than a prefab-it’s a rethink of how power should be deployed.

Faster, Smarter, Scalable

The numbers speak for themselves:

– Traditional Stick Builds: 6-12 Months to deploy

– E2V IPM: Up to 70% faster-some sites go live in just one day

– Scalable Design = Easier Upgrades, Simplified Permitting, and Repeatable Builds

As the US races toward its 500,00-charger goal by 2030, speed and simplicity aren’t just nice to have – they are mission critical. Whether you’re a utility, fleet operator, or private developer, integrated skid solutions are the clear path forward.

Build The Future -Faster

Why stick with outdated methods when you can power up in a fraction of the time? Let’s accelerate your next EV infrastructure project. Reach out to AK Power Solutions at sales@akpowers.com to see how our E2V IPM can cut timelines, reduce complexity, and keep you ahead of the curve.

References